It’s hard to put into words how we come up with what we decide to build. We feel most things have already been done, so it’s up to us to put a Grisolia spin on them, evolving old things into new things. We draw from the toys of our past, current technology, and new trends as sources for our inspiration. We are most creative when our hands are busy. We usually start a concept with an excited conversation pantomiming movements and sketching on paper or dry board possibilities.

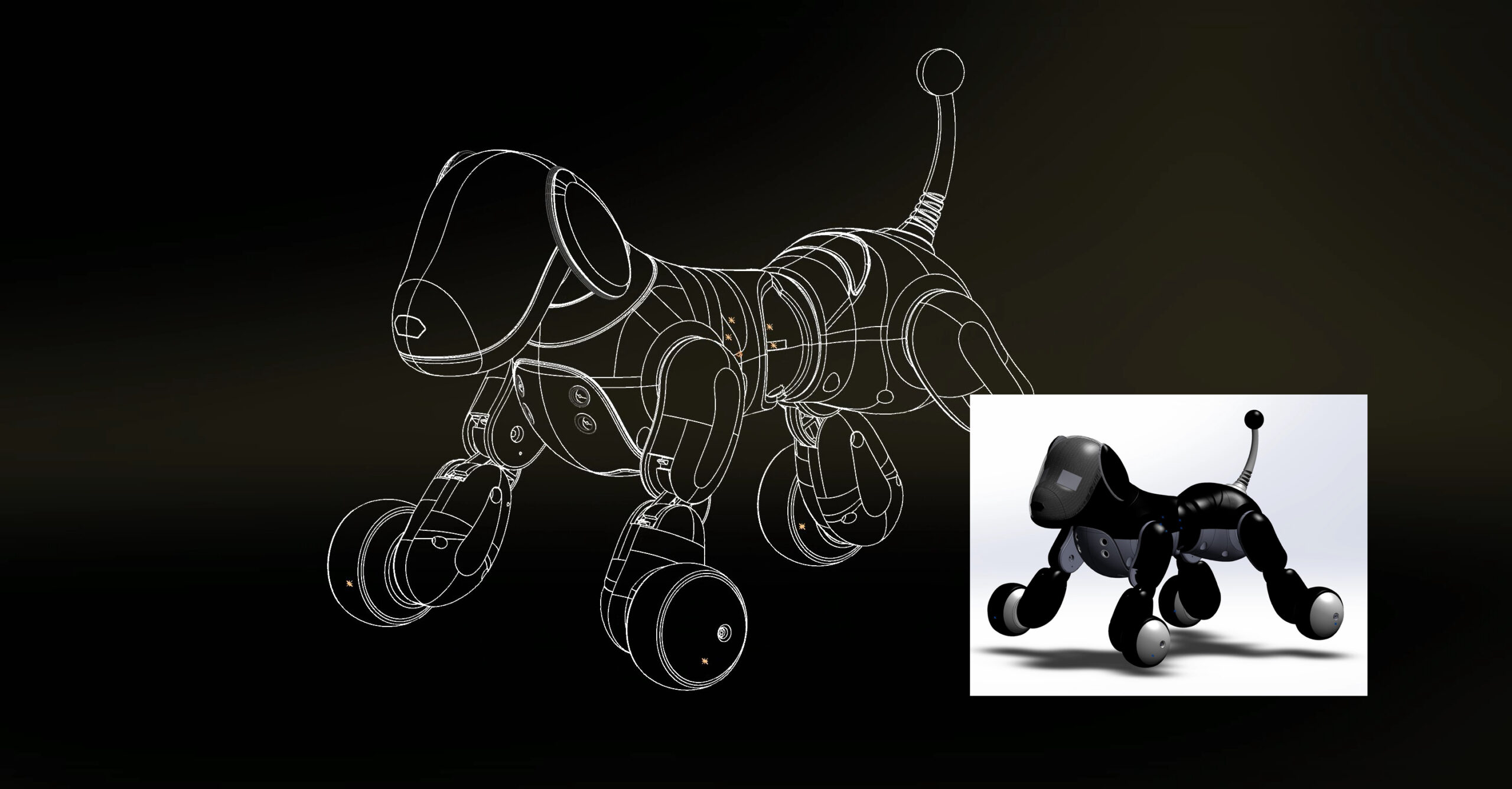

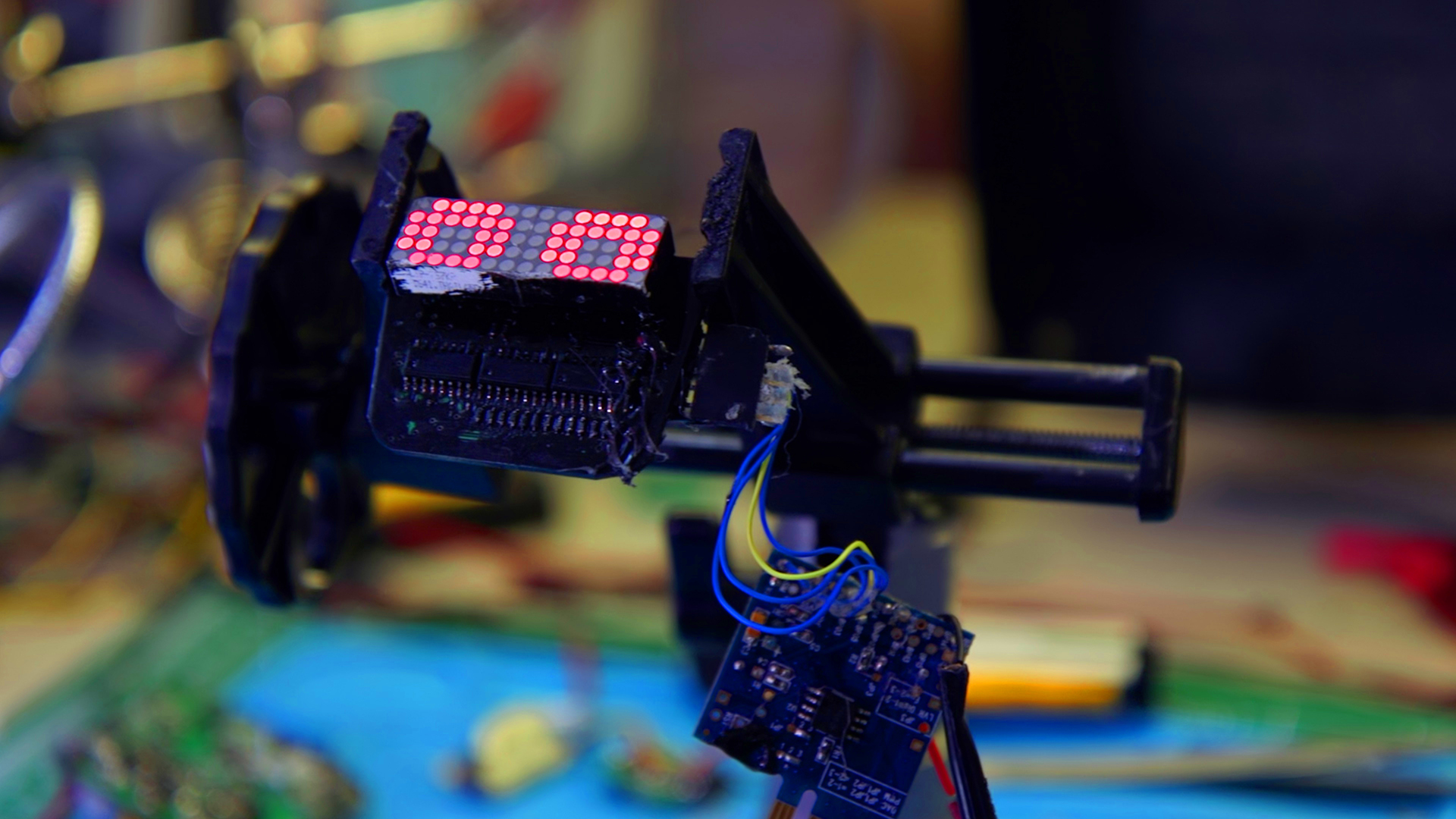

We know when the team gets excited it’s time to start bringing it into reality. Our design process is iterative we learn by trial and error sometimes several passes are needed to get something working properly. We start with a proof of concept. We begin by designing whatever key features we have in mind. While we are figuring out the mechanical logistics we then start to figure out what special controls we may need for testing, sometimes simple motor on/off control other times we need something more complex.

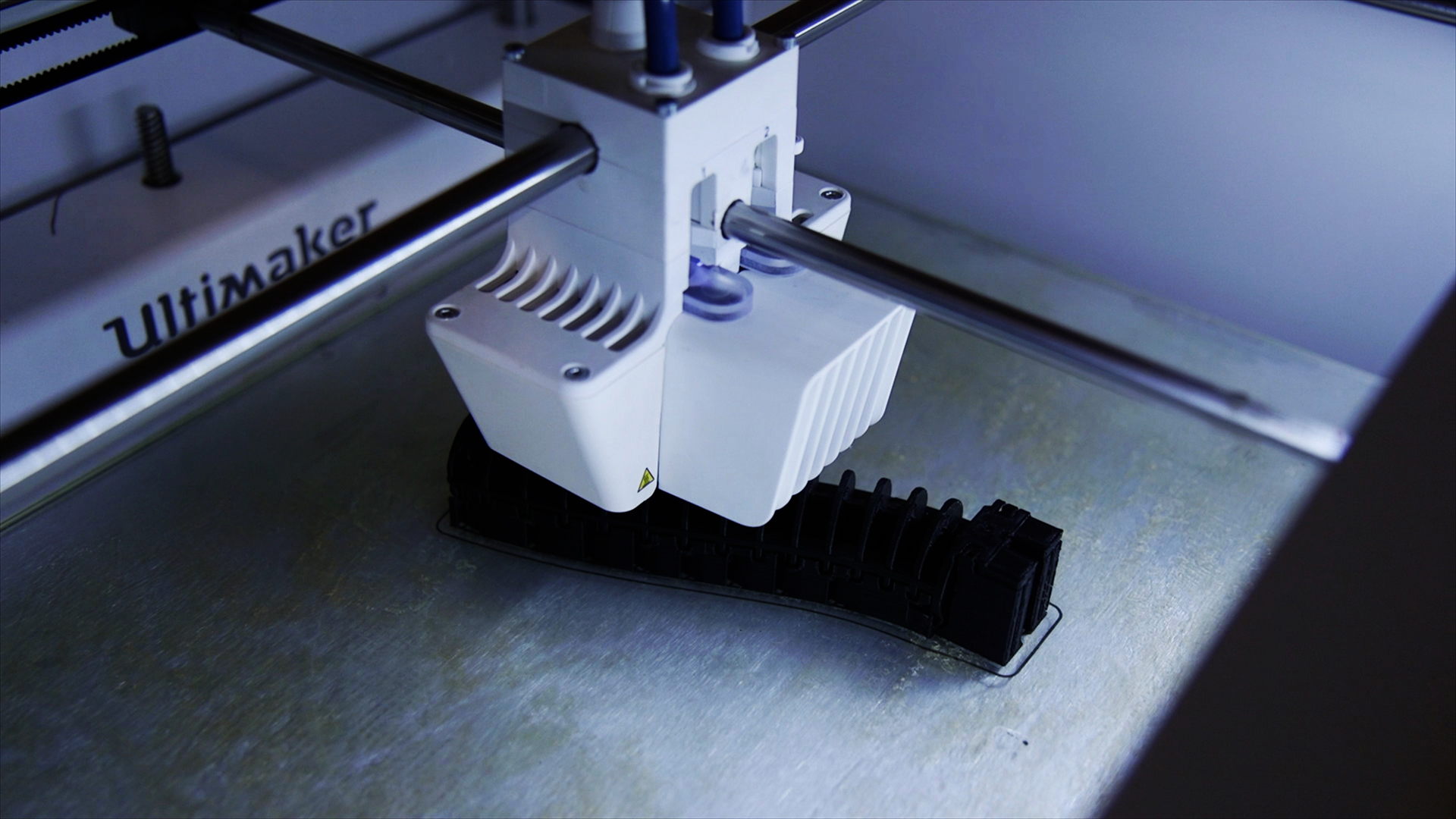

When a mechanical design is done its printed on in house 3d printers, then assembled. While parts are printing electronics controls are build and test firmware is coded. When both are fully completed we integrate the controls with physical model. The magic moment where we first see if what we made is anywhere close to what we envisioned. We will take what we have learned from the proof of concept and go back through the design-prototype process until we are ready to present the concept.

When a manufacture licenses a concept we make ourselves available to them for manufacturing consulting. We love to integrate with the production teams to assist in the production of our concepts. This has lead to our greatest successes. Grisolia clients typically apply their own aesthetic designs, and scripting to our concepts to make them fit their brand needs. We work with the brand teams, and the product development teams to make sure we fit the item to their positioning while not losing the magic of the concept, providing mechanical designs, electronics designs, and production firmware as needed. We stay with the project from kick off to production and we start assisting in solving any problems whether mechanical or electrical traveling all the way to the factory floor as needed, and we love it!